Clayton's Woollen Mill on the Blackwater

In 1867, 2 brothers

Frederick and John Clayton,

sons of John Clayton, Holme Top Mills

in Horton, Yorkshire (which had been in business for 200 years) took over the vacant mill at

Millbrook on the Blackwater,

just outside Navan.

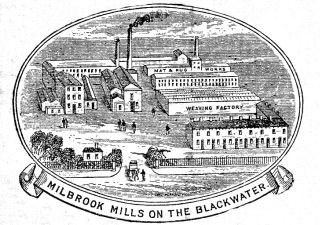

They immediately began a programme of enlarging and modernising the premises. In 1882 a new weaving shed was completed, and a few years later a large chimney shaft was constructed.

They immediately began a programme of enlarging and modernising the premises. In 1882 a new weaving shed was completed, and a few years later a large chimney shaft was constructed.

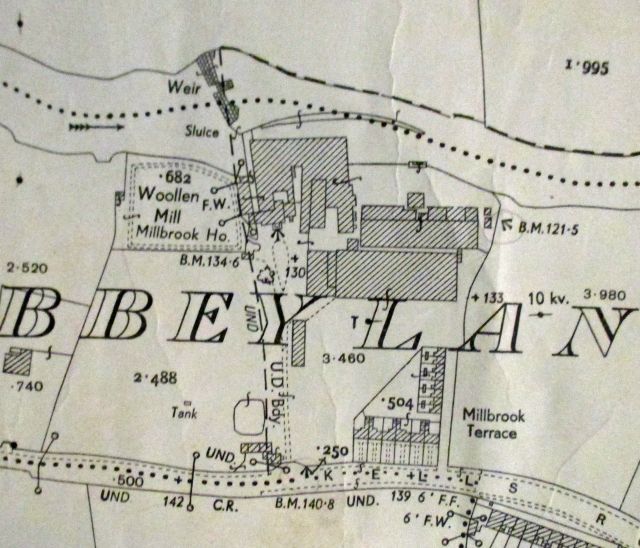

In 1882 a row of 14 houses Millbrook Terrace was built by William Curry & Sons from Navan, at a cost of £2000, to accommodate the workers.

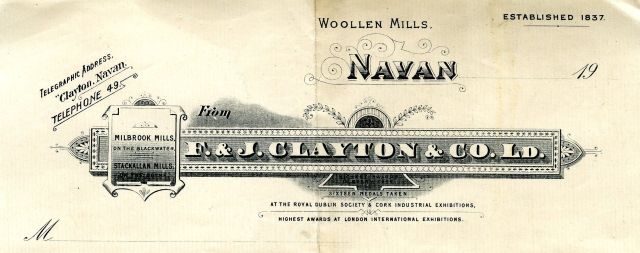

Sketch (left) from an 1942 letterhead from Claytons, thanks to Raymond Cullen.

These houses were rented to the workforce, some for 3/- and others for 5/- per week. The firm further expanded, taking over the old cotton mill at Stackallen. At this point it was one of the largest employers in the area, employing over 250 people. Generations of local families worked and lived at Millbrook.

From a report in the Meath Chronicle 1887:

From a report in the Meath Chronicle 1887:

"Five minutes brings the visitor from the Great Northern Railway station to the entrance on the Kells Rd where the first object that attracts attention is

Millbrook Terrace.

From this gate, an avenue shaded by lofty beeches brings us to the residence of the courteous manager Mr John Gallagher.

The factory buildings adjoin, conspicuous among them the great chimney shaft which reaches an enormous height and can be seen for miles around."

Large scale O.S. Map showing the location of Clayton's Woollen Mill on the R. Blackwater and Millbrook Terrace facing the Kells Road at the entrance to the Mill.

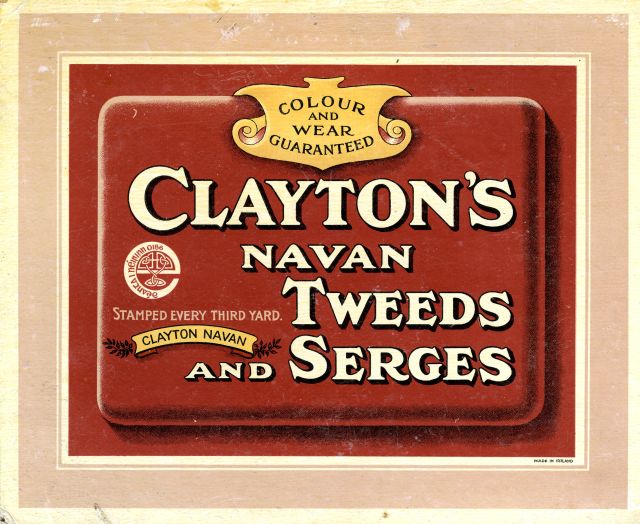

Claytons became known for the excellence of its products. It tanned and dyed sheepskins for making rugs, muffs and slippers. Its products included tweeds and serges, friezes and blankets flannels and knitting yarns. Local farmers could take the wool from their flocks to Claytons to be converted into tweed and blankets.

After exhibiting at the Irish Exhibition of Arts and Manufactures in 1882 and at the Edinburgh Exhibition, where they won medals, Claytons presented Queen Victoria with a dress, costume and travelling plaid made entirely of Irish wool.

Their dispatch books for 1939 show:

"20 bundles grey worsted and 102 bundles of black worsted to be dispatched to the Artane Industrial School Dublin; and the Priory in Killarney Co. Kerry ordered "brown habit, cut in 3 lengths, 5 yds each per post in 3 parcels."

In 1940, there was an order from the Controller of Stores Dublin for 25,000 yds of army serge for the Irish Free State Army.

(above) The Weir on the Blackwater behind Clayton's Mill, as it is today. (2014) See also the O.S. map above.

The mill was originally powered by a water wheel driven by the waters of the R. Blackwater. Power was transmitted by a series of shafts, belts and pulleys to the mill. Eventually, a ship's engine driving a large generaor was installed to provide electrical power. The boiler for the engine was fired by solid fuel. The coal arrived at the Railway Station, where it was shovelled by hand into horse drawn coal carts and transported to the mill. Turf was bought locally and stacked in long rows in the factory grounds. Timber was also used - 2 men were employed to chop this timber.

In one week, in 1942, when the mill was working a six day week (because of the wartime boom), the boiler consumed 7 tonnes coal, 10 tonnes timber and 3 tonnes turf. This amount of fuel powered enough "steam up" for 50 hours work. The boiler was cleaned out every 3 months, taking 3 days and 7 men to complete the process. Two men did the actual cleaning out. One man got into the boiler feet first and then threw the ashes out with a shovel. The ashes were wheeled to a horse drawn cart and drawn to a dump at O'Growney Tce. This area was known as "Rat Pits". There was another dumping area at St. Finian's Tce.

Clayton's Mill was connected to the ESB in 1942 at a cost of £2,184.

In the early 1920s, a son of the Clayton family was drowned in the R. Blackwater. Shortly after this, the family sold out and returned to England. The factory was taken over by a consortium of local business men headed by Mr James Sheridan who owned premises in Trimgate St. The Clayton name was retained by the new management.

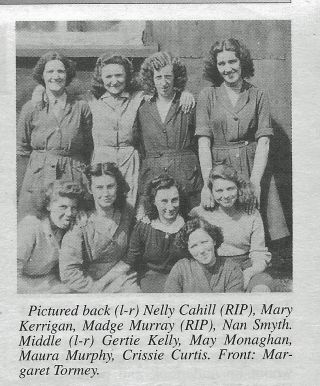

(above) Mary Kerrigan and Johnny Monaghan,

who worked in Clayton's

in the late 1930s.

(left) Mick and Sally Coogan

worked in Clayton's Woollen Mills

for over 60 years.

Photo dates c. 1920

Annual Dinner Dance in the Central Hotel Navan 1963

(Back, l to r) Paddy Rattigan, Margaret Smyth, Patsy Mallon, Kitty Smyth, Ollie Martin.

(Front, l to r) Theresa Byrne, Stanley McDonagh and Madge Mallon

George Linscheid came to Claytons as General Manager in the 1950s. He was born in Krakow in Poland in 1924 and served in the Polish Army in WW2. He spent time in a concentration camp before fleeing to England after the war. His family in Poland had been mill owners, and he was very knowledgeable on the workings of a mill. He was often referred to in Claytons as "the nine trades tradesman", as he could do winding, weaving, warping and fix a loom. He was very kind to his staff, often advancing them money.

While in Claytons he would regularly send food parcels back to his family in Poland. He remained in Claytons until its closure in the 1960s.

Sources:

Meath County Library Services (Local Studies) Navan - Letterhead and Poster

Photos of Clayton's Staff and additional information:

One Hundred Years of Life and Times in North Leinster, The Meath Chronicle Centenary Publication (1997) pp. 294-5

The Waters of the Boyne and the Blackwater, Cyril Ellison

Clayton's Woollen Mills Navan 1867-1967 Jean Thornton pub. in "Studies in Local History"

ed. Liam McNiffe